Air-Cooled Single Phase Aftercoolers

Air-cooled single phase aftercoolers are designed to cool compressed air in systems powered by single-phase electrical sources, commonly used in smaller industrial setups and workshops. These aftercoolers efficiently lower air temperatures from 200°F or higher to within 10-20°F of ambient, condensing moisture for removal. This process delivers cleaner, drier air, protecting equipment and enhancing performance in applications such as automotive repair, small-scale manufacturing, and woodworking.

- Extended Equipment Life: Cools compressed air to minimize thermal stress on system components, prolonging the lifespan of compressors and tools.

- Enhanced Air Quality: Removes moisture from compressed air, providing clean, dry air for sensitive workshop and industrial applications.

- Optimized Efficiency: Reduces air temperature to improve system performance and lower energy consumption in single-phase setups.

Air-Cooled Compressed Air Heat Exchangers

AHP Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- High Performance

- High Flows: 400-3,500 CFM

AHPH Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- High Performance

- High Flows: 400-3,500 CFM

AOL Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- Full Line of Sizes & Features

- High Flows: 400-3,500 CFM

AA Series:

Air-Cooled Aftercooler

- Full Line of Sizes & Features

- Energy Efficienct

- Medium Flows 80-300 CFM

CC Series:

Air-Cooled Aftercooler

- Full Line of Sizes & Features

- Energy Efficienct

- Medium Flows 80-300 CFM

ACOC Series:

Air-Cooled Aftercooler

- Combination Welded Cores (Air/Oil)

- Vertical Air Flow / Compact Design

- Excellent for Field Conversions

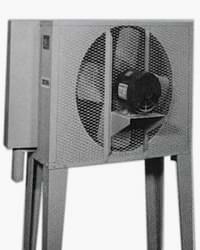

UPA Series:

Air-Cooled Aftercooler

- Full Line of Sizes and Features

- High Performance

- High Flows 400-3,500 CFM

HiRoss Aftercoolers

Air-Cooled Aftercooler

- Energy Efficient

- Full Line of Sizes & Features

- Rigid and Durable Air In/Out Conn.

IPAC Aftercoolers

Industrial Applications

- Heavy Duty, Compact Design

- Low Energy Cost

- Rigid and Durable Air In/Out Conn.

The moisture reduction provided by air-cooled single phase aftercoolers is critical for small-scale applications. Industries such as automotive repair, woodworking, and small manufacturing rely on compressed air for tools, sprayers, and machinery, where excess moisture can corrode equipment, damage finishes, or compromise product quality. By removing water vapor, these aftercoolers ensure high air quality, reducing maintenance needs and equipment wear. While additional air dryers may be used for ultra-dry air, aftercoolers lighten the drying load, enhancing efficiency and extending dryer lifespan.

These aftercoolers also safeguard the compressor system itself. In single-phase setups, compressors are often paired with filters, piping, and tools, all vulnerable to hot, moist air. By cooling air and removing moisture early, air-cooled single phase aftercoolers prevent corrosion and clogging, minimizing maintenance costs and downtime in workshop environments.

Energy efficiency is a key concern in single-phase systems, where power availability may be limited. Hot compressed air can reduce tool performance and increase compressor strain. Air-cooled single phase aftercoolers deliver cooler, denser air, optimizing equipment performance and reducing energy consumption, making them ideal for small-scale industrial and workshop applications.