Positive Displacement Compressor Cooling

Aftercoolers are vital for positive displacement compressors, ensuring effective cooling of compressed air to remove heat and moisture. This process enhances system efficiency, prevents corrosion, and maintains air quality for industrial applications like manufacturing and automotive.

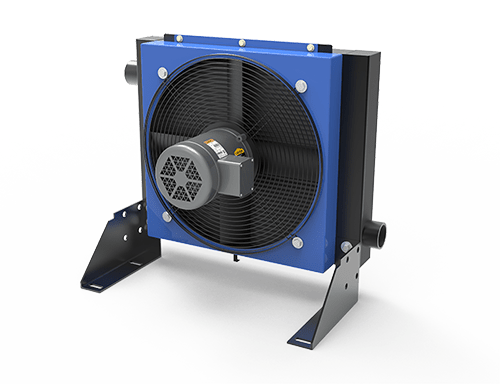

- Air-Cooled Aftercoolers: Air-cooled aftercoolers use ambient air to cool compressed air, ideal for rotary screw compressors in water-scarce environments.

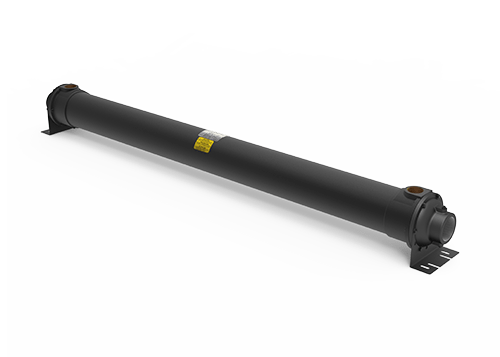

- Water-Cooled Aftercoolers: Water-cooled aftercoolers provide high-efficiency cooling for reciprocating compressors, achieving approach temperatures of 10-15°F.

- Moisture Separators: Moisture separators remove condensed water post-cooling, critical for maintaining air quality in positive displacement systems.

- Materials: Available in durable materials like copper tubes, steel shells, and optional CuNi for corrosive environments, ensuring longevity.

- Rotary Screw Compressors: Rotary screw systems benefit from aftercoolers to manage high CFM outputs and continuous operation.

- Reciprocating Compressors: Aftercoolers are essential for reciprocating compressors to handle high discharge temperatures.

Air-Cooled Aftercoolers:

Efficient cooling for compressed air systems

- Manufacturing

- Automotive

- Portable Compressors

Water-Cooled Aftercoolers:

High-efficiency compressed air cooling

- Chemical Processing

- Power Plants

- Food & Beverage

Aftercoolers for Positive Displacement Compressors

Aftercoolers are essential for positive displacement compressors, including rotary screw and reciprocating types, to cool compressed air and remove up to 75% of moisture content. They reduce air temperatures from 200-350°F to safe levels, protecting equipment and ensuring air quality for applications in manufacturing, automotive, and food processing.

These aftercoolers are designed for durability, using materials like copper tubes and steel shells, and support energy efficiency by minimizing pressure drops. Available in air-cooled and water-cooled configurations, they cater to various compressor sizes and industrial needs, ensuring compliance with operational standards.

Understanding the Need for Cooling in Positive Displacement Compressors

Positive displacement compressors trap and compress air, generating significant heat (up to 350°F) due to the compression process. Without cooling, hot compressed air retains moisture, leading to corrosion, equipment damage, and reduced efficiency. Aftercoolers cool the air to within 10-20°F of ambient temperature, condensing moisture for removal via separators, ensuring dry air for downstream processes.

Effects of High-Temperature Compressed Air

High-temperature compressed air from positive displacement compressors can degrade system components, increase maintenance costs, and compromise air quality. For example, a 200 CFM compressor at 100 PSIG can introduce 45 gallons of water daily without cooling, affecting tools and products. Aftercoolers mitigate these risks by cooling air and removing moisture, preserving system integrity.

Controlling Temperature in Compressor Systems

Effective temperature control is crucial for positive displacement compressor performance. Aftercoolers use ambient air or cooling water to transfer heat from compressed air. A significant temperature difference between the compressed air and cooling medium ensures rapid heat transfer, with water-cooled aftercoolers achieving tighter approach temperatures (10-15°F) for high-efficiency applications.

Regulative Cooling Processes

Regulative cooling in positive displacement compressors involves cooling compressed air to safe temperatures and removing moisture. For example, air is cooled from 300°F to 80°F, then passed through a moisture separator. This process is energy-efficient, as cooled air reduces the load on dryers, and some systems recover heat for other uses, lowering operational costs.

Types of Aftercoolers for Positive Displacement Compressors

Aftercoolers for positive displacement compressors are designed to handle high temperatures and moisture levels. The key types include:

Air-Cooled Aftercoolers

- Most common for rotary screw compressors, using ambient air for cooling.

- Ideal for portable or water-scarce environments, cooling air to within 15-20°F of ambient.

Water-Cooled Aftercoolers

- Used for reciprocating compressors and stationary systems with cooling water access.

- High-efficiency cooling with approach temperatures of 10-15°F, suitable for high-CFM applications.

Integrated Aftercoolers

- Built into some positive displacement compressors for compact cooling solutions.

- Suitable for smaller systems but may require additional standalone aftercoolers for high loads.

Custom Aftercoolers

- Tailored for specific compressor models or applications, handling extreme temperatures or pressures.

These aftercoolers ensure efficient cooling, moisture removal, and system reliability for positive displacement compressors in various industrial settings.